Crawler cranes are indispensable in the realm of heavy lifting and construction, known for their robust capacity and versatility. At the heart of a crawler crane's performance is its undercarriage, a critical component that provides stability, mobility, and support. This article delves into the intricate functions of the crawler crane undercarriage, exploring its components, operational significance, and the benefits it brings to heavy-duty lifting operations.

Components of the Undercarriage

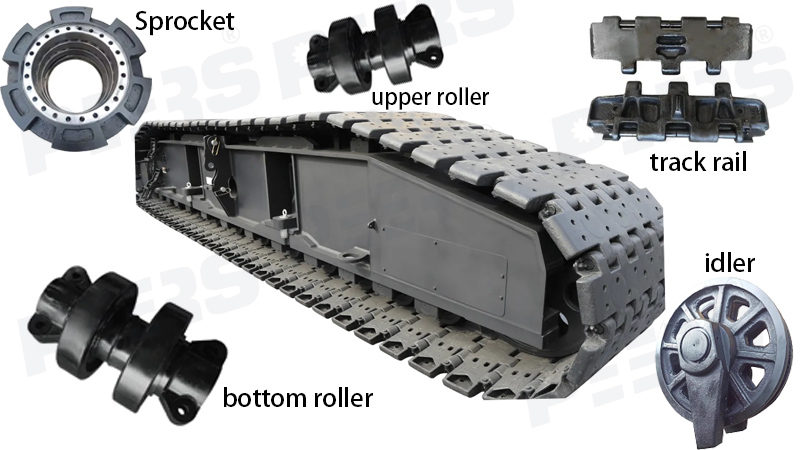

The undercarriage of a crawler crane comprises several key components:

No.1: Tracks: The tracks, often referred to as crawlers, are made of high-strength steel and are designed to distribute the crane's weight evenly across a large surface area. This design prevents the crane from sinking into soft or uneven ground, ensuring stable operation.

No.2: Track Frame: The track frame is the structural base that supports the tracks and connects them to the main body of the crane. It is engineered to withstand substantial loads and stresses, providing the necessary strength and durability for heavy lifting tasks.

No.3: Slew Ring (or Slewing Bearing): This critical component enables the upper structure of the crane to rotate 360 degrees. The slew ring is located between the undercarriage and the superstructure, facilitating smooth and precise movement of the crane’s boom.

No.4: Hydraulic Motors and Drives: Hydraulic motors power the tracks, enabling the crane to move. These motors are controlled by the operator and provide the necessary torque and speed to maneuver the crane efficiently.

No.5: Bottom rollers, Upper rollers and Idlers: These components support the weight of the crane and ensure the tracks move smoothly over the ground. Rollers distribute the load evenly, while idlers help in maintaining track tension.

Functionality of the Undercarriage

The undercarriage's primary function is to provide a stable and mobile base for the crane. Here are the key functions it performs:

A. Stability: One of the most crucial roles of the undercarriage is to ensure stability, especially when lifting heavy loads. The wide track base spreads the weight, reducing ground pressure and preventing tipping or sinking.

B: Mobility: The tracks allow the crane to move across various terrains, including soft, uneven, and rugged surfaces. This mobility is essential for reaching different parts of a construction site or moving between sites.

C: Support for Lifting Operations: The undercarriage supports the superstructure and the boom, ensuring that lifting operations are conducted safely. The robust design and construction of the undercarriage components help in handling the dynamic loads experienced during lifting.

D: Rotation and Precision: The slew ring enables the crane to rotate, providing the flexibility to position loads accurately. This capability is vital for tasks that require precise placement of heavy materials.

Benefits of a Well-Designed Undercarriage

A well-designed undercarriage brings several benefits to the operation of crawler cranes:

1. Enhanced Safety: Stability is paramount in crane operations. A reliable undercarriage minimizes the risk of accidents by providing a steady base, even on challenging terrains.

2. Operational Efficiency: The ability to move smoothly and position loads precisely enhances the overall efficiency of construction projects. Operators can rely on the crane to perform tasks accurately and swiftly.

3. Versatility: Crawler cranes are used in a wide range of applications, from construction to heavy industrial tasks. The undercarriage’s ability to handle different terrains and conditions makes these cranes extremely versatile.

4. Durability and Longevity: High-quality materials and engineering in the undercarriage components ensure long-term durability. This longevity translates to reduced maintenance costs and downtime, enhancing the crane’s productivity.

So the undercarriage of a crawler crane is a foundational element that determines the crane’s performance and reliability. By providing stability, mobility, and support, the undercarriage enables crawler cranes to tackle some of the most demanding lifting tasks in various environments. Understanding the intricacies of the undercarriage components and their functions highlights the importance of this critical system in ensuring safe, efficient, and versatile crane operations. As technology advances, innovations in undercarriage design will continue to enhance the capabilities of crawler cranes, cementing their role as essential tools in construction and industrial projects worldwide.

if there are any questions need us help, please contact Quanzhou PEERS Construction Team, we will be happy to be helped!